Coming up with a new product idea is exciting. Yet before you manufacture a product en masse, it’s essential to ensure all the parts work and your customer base needs the product. Prototypes are designed to determine the functionality of a product and the costs associated with manufacturing.

Each day, millions of entrepreneurs around the world register their new companies. Competition is fierce, especially on a global level. The only way for non-service brands to get ahead is to test, refine and release new products.

If you create any type of good, knowing how to navigate prototype creation can help improve overall profits and success.

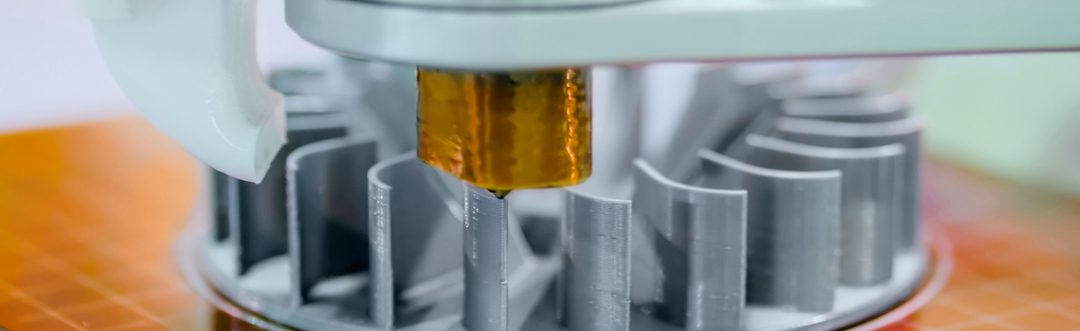

1. Utilize 3D Printers

These devices, able to print prototypes on the spot, drive modern manufacturing. In fact, 80 percent of companies say the technology allows them to come up with innovations faster than before.

Small businesses no longer have to pay outrageous fees to design and refine a product. Now, they can change dimensions on the fly, perfect them virtually then print the prototype on-site.

2. Try Different Materials

The materials you use in your finished product impact both the cost of production and the overall quality. Prototyping allows you to try different types of materials and see which performs best.

You might find steel is too heavy but plastic breaks too easily. You can then look at alternatives, such as aluminum for durability and lighter weight. Prototyping allows you to test the cost, function and endurance of a variety of materials.

3. Choose a Type

There are several different types of prototyping methods. You can save time and money if you know which one to use during development. For example, you might brainstorm ideas with sketches and diagrams.

Narrow the options down to one or two designs, then create a digital prototype. Once you’ve perfected the product, it’s time to move to 3D printing. Knowing the types of prototyping available — and the best one to use — can save you time and money.

4. Save Time with CAD

Computer-aided design (CAD) allows you to take a concept and craft it into a finished piece. CAD is a cost-effective way to create a new product and make significant changes. For example, most automotive manufacturers start with sketches and CAD designs before building a prototype of a larger vehicle.

Creating model after model without perfecting your idea is costly. CAD concepts are easy to share with team members, an ideal way to gather feedback on potential changes.

5. Conduct User Research

The prototype phase is the best time to gather information from your target audience about what they do and don’t like. Arguably, the most crucial stage of the development process is input from those who will use your product.

User-centered research helps you determine ways to make the finished item even better. Alternatively, you may take elements of the design that aren’t working and fix them before manufacturing.

6. Remember Die Casting

Die casting, first introduced as a production method in the 1800s, still has a place in modern manufacturing. The majority of production dies must be recast, especially if you’re conducting extensive testing. A single-cavity die casting process allows you to ensure all little changes are in place and functioning as expected.

Die casting will save money later on when you discover you forget to implement a change, or the product doesn’t function as it should. However, there are other casting methods as well, such as the inexpensive gravity casting rapid prototyping.

7. Think About Investors

If you plan to bring investors in, a working prototype allows you to show them what they’re investing in. Put yourself in the shoes of the person sitting across the table. Why should they trust your vision is one that will become profitable? How will they get their money back?

If you already have a prototype and have done both user and market testing, they are more likely to see your idea is a viable one.

8. Take Pre-orders

You’ve likely seen concept products listed on crowdfunding sites such as Kickstarter and Crowdfunder. Smaller companies can create a single prototype of an exciting new product and showcase it via images, video and description.

Next, brands advertise the product on social media. Users can pre-order the product, money which is used to jumpstart the manufacturing process. The business creates the product and those who invested receive the first items off the line.

9. Test Like Crazy

When you’re creating a new product, you want consumers to be happy with the finished result. Before you manufacture a new design, spend time testing the prototype as much as possible. Ensure parts don’t break and that it continues to function as promised. Test every type of scenario you can think of.

How does your invention hold up if doused with water? What about in extreme heat or cold? Use your product until you’re sure it will withstand some abuse. Then, back up your design by sharing test results in your marketing efforts.

Seek Perfection

You want to make the perfect product. Yet you can’t jump straight to manufacturing. Create a design that will stand the test of time with prototypes and testing. Create a plan for dealing with complaints or issues as they crop up.

A successful design requires constant optimization. If you can inexpensively make improvements over time, you can quickly develop a loyal customer following.

————————————————————–

By: Lexie Lu

Lexie is a web designer and UX strategist. She loves taking her goldendoodle on long runs and checking out local flea markets. Follow her on Twitter @lexieludesigner.